As industries evolve through digital transformation, 2025 is set to be a crucial year for industrial automation advancements. Integrating robotics, Artificial Intelligence (AI), and the Internet of Things (IoT) will streamline production, improve accuracy, and minimize waste. Let’s explore how Enterprise Resource Planning (ERP) solutions like IFS are shaping the future of automation, enabling businesses to achieve unprecedented efficiency, precision, and scalability.

Industrial Automation Trends in 2025

Several key trends are defining industrial automation in 2025:

- AI-Powered Vision Systems: AI is the cornerstone of modern machine vision, with deep learning models detecting minor defects and adapting to dynamic production environments in real-time.

- Edge Computing: Edge computing ensures immediate insights, empowering decision-makers and reducing downtime.

- Collaborative Robots (Cobots): Cobots enhance human-machine collaboration, assisting in defect identification, reducing strain on workers by automating repetitive tasks, and improving precision in various processes.

- IIoT: The Industrial Internet of Things (IIoT) connects devices, sensors, and machinery, providing real-time data for enhanced monitoring and control. By 2025, more industries will leverage IIoT for end-to-end automation and resource optimization. The IIoT market is predicted to exceed $1 trillion by 2025, highlighting its transformative potential.

- Plug & Produce Solutions: These standardized automation solutions offer a quick way to optimize processes without lengthy integration.

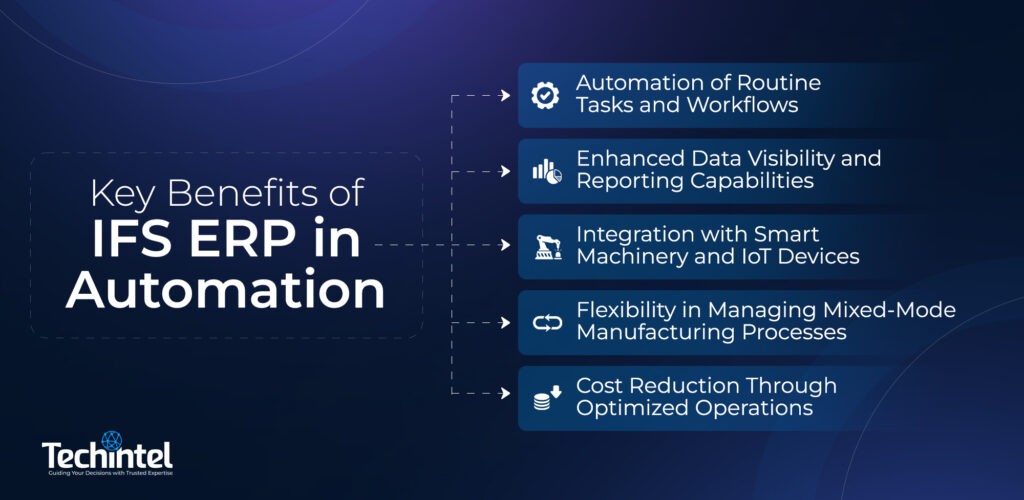

Key Benefits of IFS ERP in Automation

IFS enables manufacturing companies to optimize their processes by automating certain activities, therefore increasing productivity. IFS provides a comprehensive view of all business processes, helping managers understand relationships between different processes and identify potential improvements, with benefits including:

- Automation of Routine Tasks and Workflows: IFS includes Business Process Automation features with a workflow engine embedded to enhance automation and tailoring. A workflow is a sequence of tasks that process a single data collection from a business and industry interaction.

- Enhanced Data Visibility and Reporting Capabilities: IFS helps improve operational efficiency by providing a comprehensive view of all business processes. This enables better understanding of the relationships between different processes and identification of potential areas for improvement.

- Integration with Smart Machinery and IoT Devices: Widespread adoption of IIoT continues to connect devices, sensors, and machinery, creating a cohesive ecosystem that provides real-time data for enhanced monitoring and control.

- Flexibility in Managing Mixed-Mode Manufacturing Processes: Automated systems that can quickly switch between production lines and product variants will become crucial. Modular production systems and cobots play a major role in this. Companies that can produce flexibly remain competitive in a rapidly changing market.

- Cost Reduction Through Optimized Operations: IFS allows manufacturing companies to reduce their costs by streamlining processes and eliminating redundant tasks. This results in significant savings in time, money, and other resources.

A Real-World Example

IFS partnered with Rolls-Royce to apply AI expertise and improve predictive maintenance on engines. They built an automated data pipeline from customers into Rolls-Royce, providing real-time in-service status of assets. This enables end-to-end sharing of data between the airline customer, IFS, and Rolls-Royce, supporting maintenance throughout the product lifecycle.

Summary

Industrial automation in 2025 is about integrating advanced technologies to achieve greater efficiency, adaptability, and precision. ERP solutions like IFS are at the forefront, offering the tools and capabilities needed to navigate this evolving landscape. By embracing these technologies and strategies, manufacturers can optimize their operations, reduce costs, and stay competitive in an increasingly dynamic market.